Industries

Textile & Fibers

Evonik offers customized solutions for the broad and highly diversified textile and fibers auxiliaries market.

Evonik offers textile formulators and manufacturers additives as main ingredients and formulation aids for improving the processability of fibers and garments to enhance the properties and quality of textile goods. Backed by our in-depth technical know-how and experience in the synthesis of organo-modified siloxanes and specialty organic surfactants, our innovative systems and solutions help our customers across the globe meet sustainability targets and achieve the complex textile label performance requirements. Our market-oriented research and development also plays an important role in supporting our customers to improve efficiencies in their production processes.

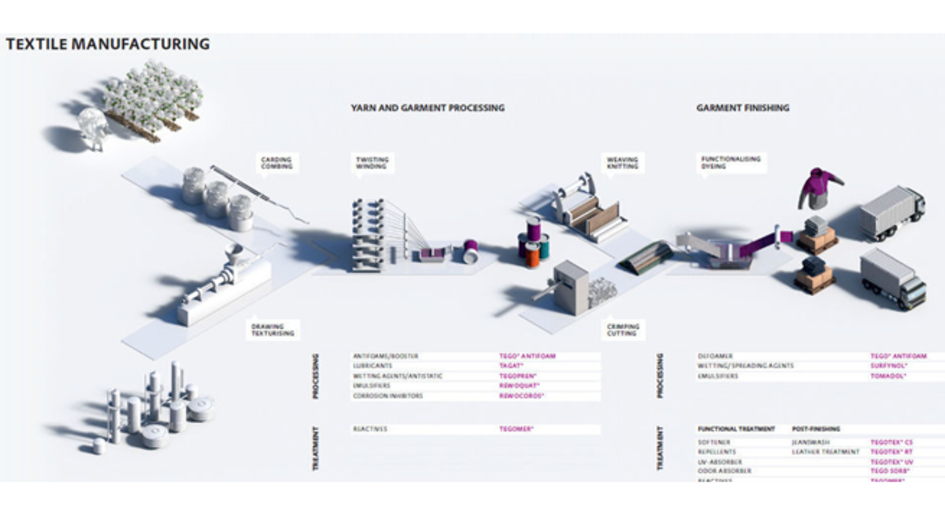

Behind the customized properties for our textile auxiliaries is a synergistic combination of specific additives that cover a diverse range of textile applications. From the wetting & spreading agents needed in yarn and garment processing, to antifoams which ensure smooth production and the water and dirt repellents, odor absorbers and softeners used in garment finishing applications for modern hardwearing fabrics, we have a unique position as a leading specialty chemicals producer for the textile and fibers auxiliaries’ industry.

- Wetting and Spreading Agents: Low molecular wetting and spreading agents help to rapidly decrease the surface tension to improve the quality of the fabric’s finish. Our TEGOPREN® polyether siloxanes provide outstanding wetting and spreading performance in textile auxiliary formulations

- Antifoams: Our additives do not have any negative impacts on the fabric quality, do not stain or disturb the washing machine runability

- Protecting Agents: Our emulsifiers and antistatic agents help to protect the garment’s fiber filaments and washing machine during washing

- Defoamers: Our defoamers prevent foam formation or are added as an external antifoam agent to destroy foam as it occurs during processing to improve final quality

- Emulsifiers: Our complete range of TOMADOL® Ethoxylated Alcohol surfactants are made from linear synthetic alcohols and are labeled to indicate the chemical structure of the surfactant

- Repellents: TEGOTEX® RT 2033 and 2040 improve the soil and water repellency of a diverse range of textiles and fabrics, but do not contain any fluorocarbons or flammable liquids making them suitable for meeting complex label requirements

- Softeners: Our extensive portfolio of softeners enables fabrics to maintain a soft, smooth or voluminous finish while also retaining hydrophilicity

- Denim Protection: Our TEGOTEX® UV 5050 provides outstanding UV protection in low concentrations to stop fading and protect the wearers skin, and is specially designed to maintain light and bright-colored fabrics

- Odor Absorber: TEGO Sorb® permanently removes odors from textiles and fabrics by chemically binding malodor causing substances together preventing them from penetrating the material

- Leather Treatment: Our specialty additives help to enhance the properties of leather products to improve the finished look and feel and increase overall durability

With increasingly more stringent environmental and sustainability label requirements, we are fully focused on supporting the textile industry to reduce the ecological and toxicological impact of the chemicals used in textile manufacturing. We help our customers to enhance their sustainable development by providing more biodegradable, non-toxic and non-sensitizing surfactants. We also work closely with the textile industry to enable it to achieve its specific requirements for reducing heavy metal content and emissions from production processes.

Evonik products for textile and fibers to increase sustainability

Our latest TEGOTEX® textile finishing products improve the durability of apparel and functional textiles to prevent peeling effects which leads to lower micro plastic emissions during washing. Our process improving additives also help reduce water and solvents use during textile manufacturing and have been developed to meet the latest consumer and environmental requirements. We offer our customers resource-saving and energy-efficient solutions for a wide range of applications. In this way, we are proud to play our part in meeting the rising sustainability requirements across all our markets.